Thanks to a 25 years experience in various industrial sectors, the 2MI team has developed a set of skills to ensure the management of a project, from its design to its commissioning in the site.

From mechanical modeling skills, the company was able to develop its skills to adapt to the market changes and develop activities in the new aircraft business.

2MI also produces tools for the automotive industry. Our skills in this sector have enabled us to gain easier access to the aeronautical market.

This is how 2MI holds several field of activity.

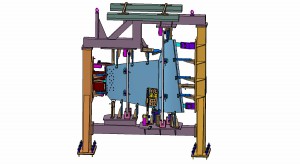

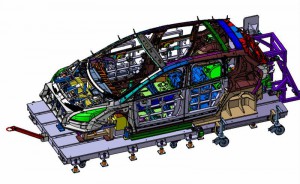

2MI design and manufacture checking and assembly fixtures, testing facilities, demonstrators and prototypes in carbon composite and glass.

Our capacity to innovate with both product and process, our skills in project management, our work expertise, our design control and simultaneous industrialization combined with our expertise in 3 or 5 axes NC machining and 3D control of large dimensions make the 2MI Group a major partner of the major contractors and automotive constructors.

Design office and Methods facilities

Our group has a design office for the design of in-house tools and we work with the latest IT resources as 3D CAD that allows the reading of STEP, DXF, DWG and IGES format files.

Softwares used

CAD : 6 stations CATIA V5 R18 to R27 volume and surface

CFAO : 2 stations WORK NC

METROLOG X4 for metrology

GPAO Windev

Services on clients sites

- Design, study with CATIA

- Digitization

- Installation and 3D control

- 3D control with laser Tracker

- Consultancy expertise in process control