Thanks to a 25 years experience in various industrial sectors, the 2mi team has developed a set of skills to ensure the management of a project, from its design to commissioning to the site.

2mi has good references in the aerospace industry.

From mechanical modeling skills, the company was able to develop its skills to adapt to the market changes and develop activities in the new aircraft business.

2mi also produces tools for the automotive industry. Our skills in this sector have enabled us to gain easier access to the aerospace market.

This is how 2mi holds several field of activity.

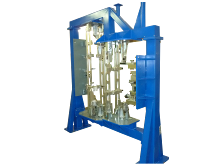

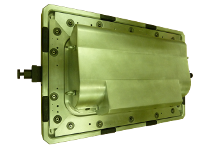

ASSEMBLY FIXTURES

The assembly fixture allows referencing several parts to assemble them in the best geometrical and dimensional requirements.

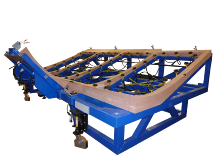

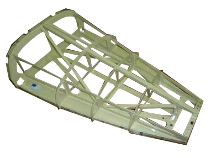

THE SPECIFIC STRETCHING, BENDING, CLIPPING AND DRAPING FIXTURES

- The clipping fixtures below designed and made in aluminum, steel or resin are intended with vacuum holding of a work piece made of composite materials or aluminum composite materials or aluminum during the clipping phase by mechanic machining phase or by waterjet cutting.

- The bending fixtures are made of steel or/and aluminum parts on a « Flow Press » type of machine.

- The stretching fixtures made of poured iron allows the shaping of aluminum parts by “drawing” of the material onto a stamp.

- The draping and molding fixtures are designed to achieve stratified carbon multilayered parts or composite parts with nucleus (foam or honeycomb) with a polymerization process under heated vacuumed autoclave.

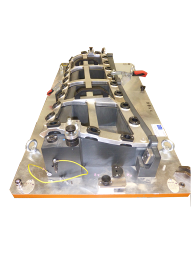

PROTOTYPES, MODELING AND DEMONSTRATORS

Prototyping models activity by implementing composite parts with production technics of carbon or fiber glass parts, milling and assembly of parts constituting demonstrators or styling models.

The French manufacturers have ranked us as a leading supplier.

We study and realize representatives sets of parts and their environment that are intended to validate functions (kinematic, mounting ability, accessibility, visibility, aspects…) or tests and trials (endurance, tightness, shocks).

THE DRILLING FIXTURES AND GRIDS

These tools are essential in the manual assembly process of components in aerospace. They are intended after referencing to serve as templates for drilling holes before the riveting operation. They are made of small or large thickness aluminum or composite materials depending on their size or their use.

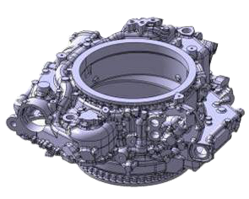

COMPLEX FOUNDRY

2MI is a leader in complex foundry tooling parts realization.

Our knowledge in the foundry business allows us to support the digitization of specifics related to the foundry and molding study following the instructions of our foundry customer.

Our molding studies are entirely made using CATIA V5 and the tools are fully machined by CNC.

Our expertise is recognized by the major international foundries.

REFERENCES